Project Details

CE Group was awarded this project and undertook it as the principal contractor for the Design and Construction works. At the core of the project was the requirement to upgrade the plant’s control systems from several stand-alone elements, of which some were manually operated, into a distributed automated PLC / SCADA solution.

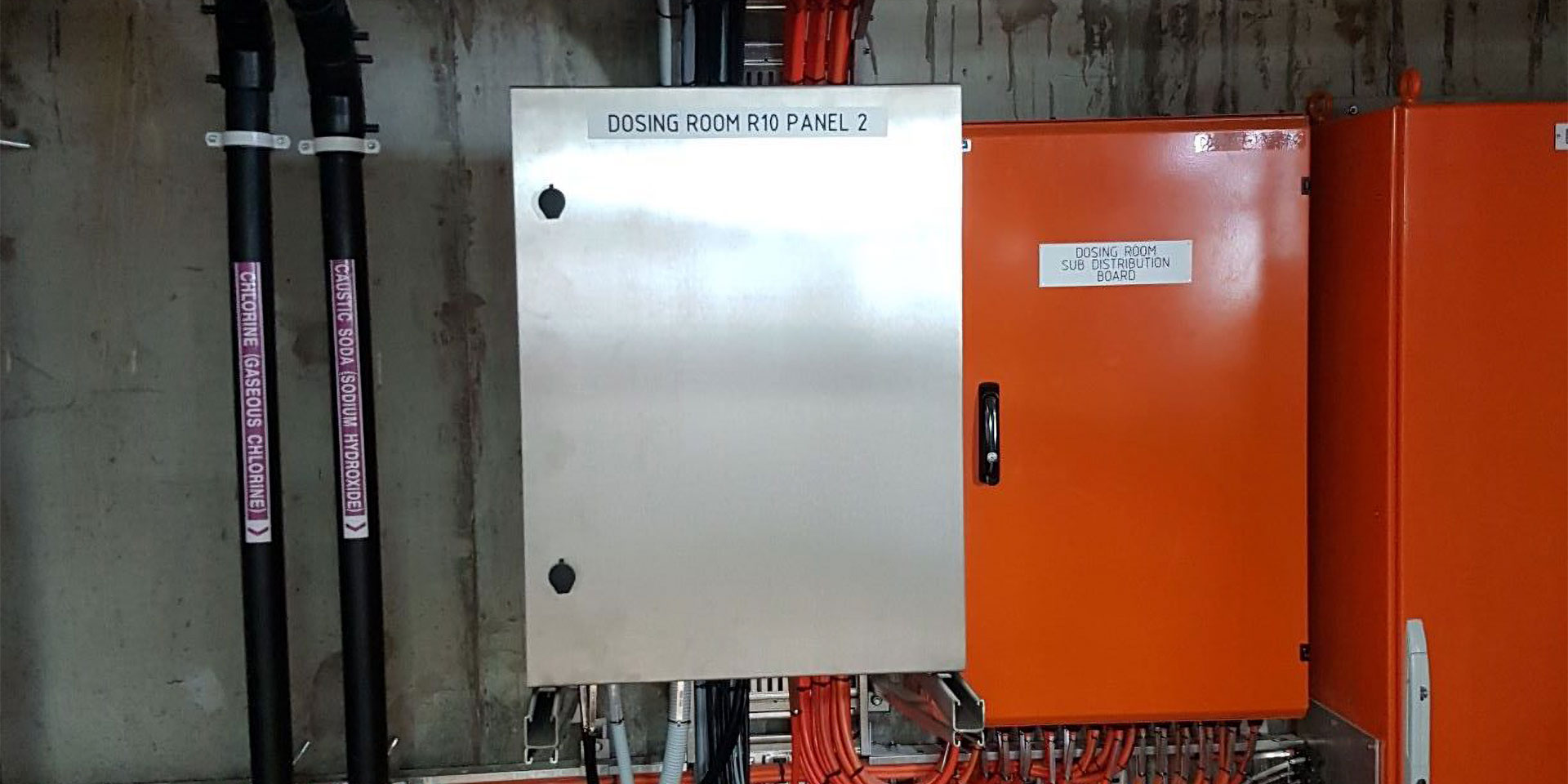

Partnerships with suitably experienced companies enabled us to perform the process and hydraulic design consultancy, as well as the mechanical design, manufacture and the commissioning of such. As part of this work brief, CE Group successfully completed the removal of the old Aeration Tower, removal and replacement of the existing asbestos water main (including dosing injection points), addition of Caustic, Alum and Chlorine Gas chemical dosing systems, automatic DN150 Filters Backwash Valving and sequencing, all alongside the control system upgrade.

The project was run under CE Group’s accredited HSEQ system to provide close controls to ensure the delivery of a safe, environmentally friendly and quality driven system to our client.

The project’s electrical aspects were all performed by CE Group including the integration of the new equipment into Seqwater’s network SCADA (Supervisory Control and Data Acquisition) system providing full equipment control, redundancy, remote access, diagnostics, reporting and historian data trending.

The delivery of this project emphasises the breadth and depth of experience CE Group has in the Industrial Electrical market, including the Water & Wastewater industry, highlighted by our below capabilities.

Examples of CE Group’s Project Management capability included:

- Qualified personnel and sub-contractor management,

- Technical knowledge of the water treatment processes,

- Process knowledge of chemical systems batching and storage,

- Industry best practices and procedures,

- Networking suitable expertise into a resourceful team culture,

- A focus on the pubic pressures based on water supply demands.

Examples of CE Group’s Design capability included:

- Consultation with the Plant’s technical, operations and maintenance personnel to exacting standards,

- In-house electrical design, including communications network design, electrical controls design and Switchboard design,

- In-house AutoCAD drafting and document controls procedures.

Examples of CE Group’s Manufacturing capability included:

- In-house welding specialists,

- In-house manufacture of Motor Control Centres, Distribution Switchboards, Control Panel and PLC Panels,

- Fully equipped assembly workshop with tooling and testing equipment.

Examples of CE Group’s Installation capability included:

- Welding specialists on staff,

- Highly experienced industrial electricians,

- Experienced instrumentation installers,

- General Light and Power requirements,

- Quality workmanship ethic.

Examples of CE Group’s Programming capability included:

- Knowledge of Siemens PLC & Citect SCADA platforms,

- Configuration of Variable Speed Drives and Instruments,

- Interpretation of the Plant’s controls requirement,

- Knowledge of Fibre Optic, Ethernet and Serial networks,

- Commissioning of complicated controls processes,

- Remote PLC communications over 3G and Wi-Fi.

Summary

Location

Client

SeqWater

Project Completion

2020

Value

##.#m

Man hours

5,500